Publication

Microfluidics has been the key component for many applications, including biomedical devices, chemical processors, microactuators, and even wearable devices. This technology relies on soft lithography fabrication which requires cleanroom facilities. Although popular, this method is expensive and labor-intensive. Furthermore, current conventional microfluidic chips precludes reconfiguration, making reiterations in design very time-consuming and costly.

To address these intrinsic drawbacks of microfabrication, Professor Lim Chwee Teck and team presented an alternative solution for the rapid prototyping of microfluidic elements such as microtubes, valves, and pumps. In addition, they demonstrated how microtubes with channels of various lengths and cross-sections can be attached modularly into 2D and 3D microfluidic systems for functional applications.

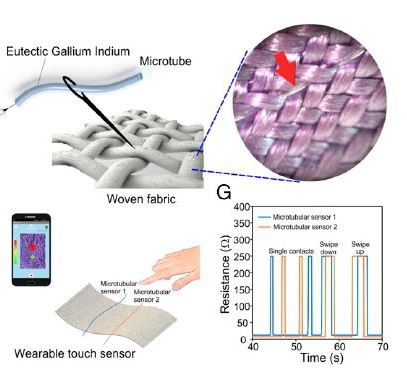

A facile method of fabricating elastomeric microtubes is introduced as the basic building blocks for microfluidic devices. These microtubes are transparent, biocompatible, highly deformable, and customizable to various sizes and cross-sectional geometries. By configuring the microtubes into deterministic geometry, we enable rapid, low-cost formation of microfluidic assemblies without compromising their precision and functionality. We demonstrate configurable 2D and 3D microfluidic systems for applications in different domains. These include microparticle sorting, microdroplet generation, biocatalytic micromotor, triboelectric sensor, and even wearable sensing.

Their approach, termed soft tubular microfluidics, provides a simple, cheaper, and faster solution for users lacking proficiency and access to cleanroom facilities to design and rapidly construct microfluidic devices for their various applications and needs.

The schematic showing the diverse applications of the microtubes in various domains: from microparticles/cells separation and droplet generation using physical force fields, to micromotor actuation using biocatalytic reactions, to triboelectric sensing using electrochemical principles, and finally to wearable sensing using physicoelectrical phenomenon.

The schematic showing the diverse applications of the microtubes in various domains: from microparticles/cells separation and droplet generation using physical force fields, to micromotor actuation using biocatalytic reactions, to triboelectric sensing using electrochemical principles, and finally to wearable sensing using physicoelectrical phenomenon.

The research paper has been published in PNAS | vol. 114 no. 40 vol. 10590–10595, doi: 10.1073/ pnas.1712195114 doi: 10.1073/pnas.1712195114